Product

Featured Products

Customized Printing Cold Seal Packaging Roll Film

Brand: CY PACK

Product origin: China

Delivery time: 25 days lead time

1. Food packaging roll film often provides excellent barrier properties, including protection against oxygen, moisture, and light. This helps extend the shelf life of food products, keeping them fresher for longer and reducing food waste.

2.Packaging roll filmensure the safety and hygiene of food products by preventing contamination from external factors such as dust,bacteria, and handling. They also come with tamper-evident features to reasure consumers of product intergrity.

3.Roll films are highly efficient in terms of material usage. They can be tailored to fit the exact size of the food products, reducing packaging waste.

4. These packaging roll film can be used with automate packaging machines, increasing production efficiency and reducing labor costs.

Customized Printing Cold Seal Packaging Roll Film

Cold seal packaging is employed for varied product like:

Chocolate bars

Confectionery

Cookies

Ice cream

Pastry

Cereal bars, among others.

Darrell Lea is an Australian company that manufactures and distributes chocolate, liquorice and other confectionery.

They chose CYPACK cold seal packaging manufacturers to customize the perfect packaging for their confectionery.

Production Process

We use the latest high-speed fixed-point coating compound machine to carry out cold-adhesive coating compounding at fixed-point parts.

Choose the best materials for your packaging

Chocolate and stick candy is extremely vulnerable to sunlight and also needs protection against oxygen, especially if there are nuts inside, so the composite materials should preserve the initial gas composition and light level in the packaging.

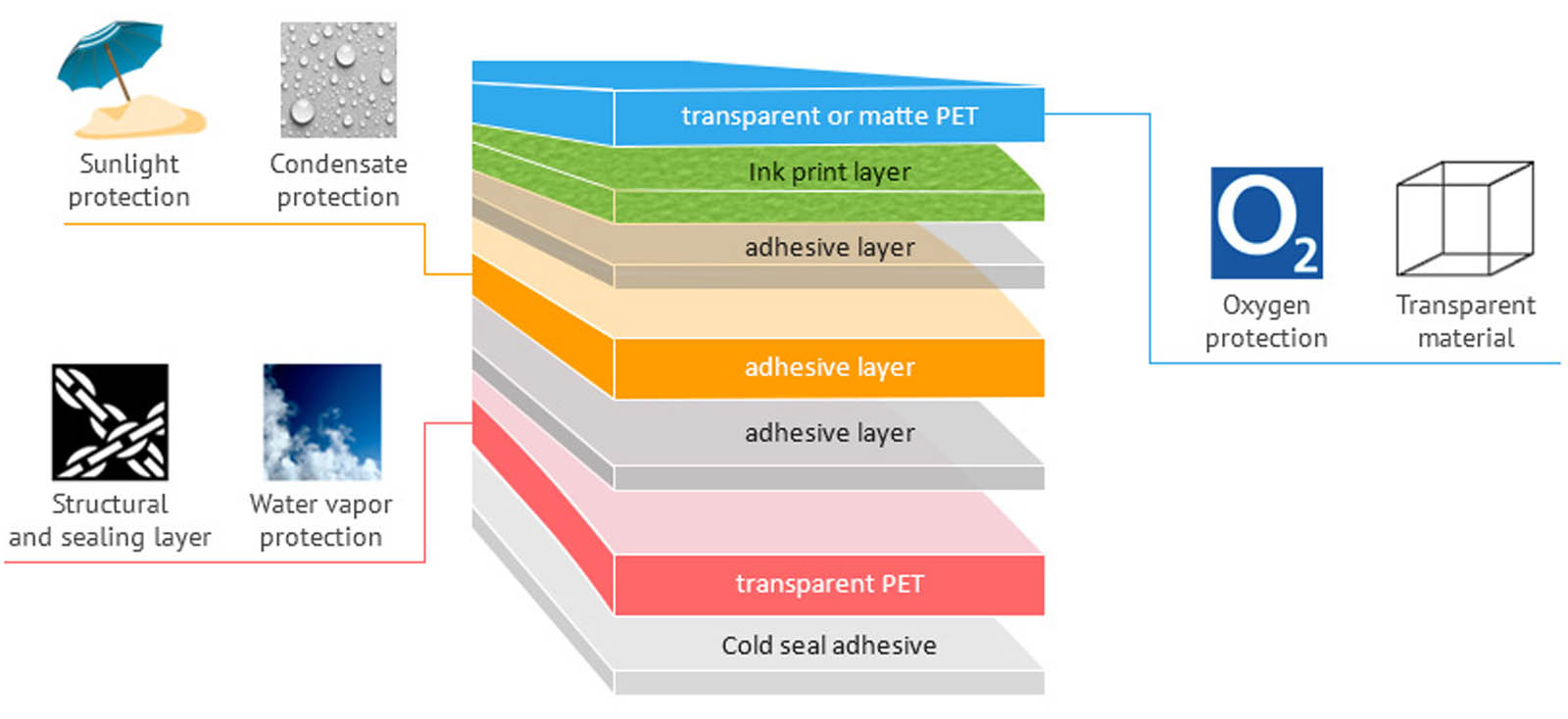

SCHEME 1 : The optimal for group chocolate sweets packaging. It is a three-layer laminate that will protect the product from sunlight and oxygen.

-

transparent or matte PET/BOPP (good barrier properties against water condensate, high transparency)

-

metalized PP (good barrier against water condensate and sunlight)

-

transparent PE (sealing and structural layer, good barrier against water vapours)

-

transparent or matte PET/BOPP (good barrier properties against water condensate, high transparency)

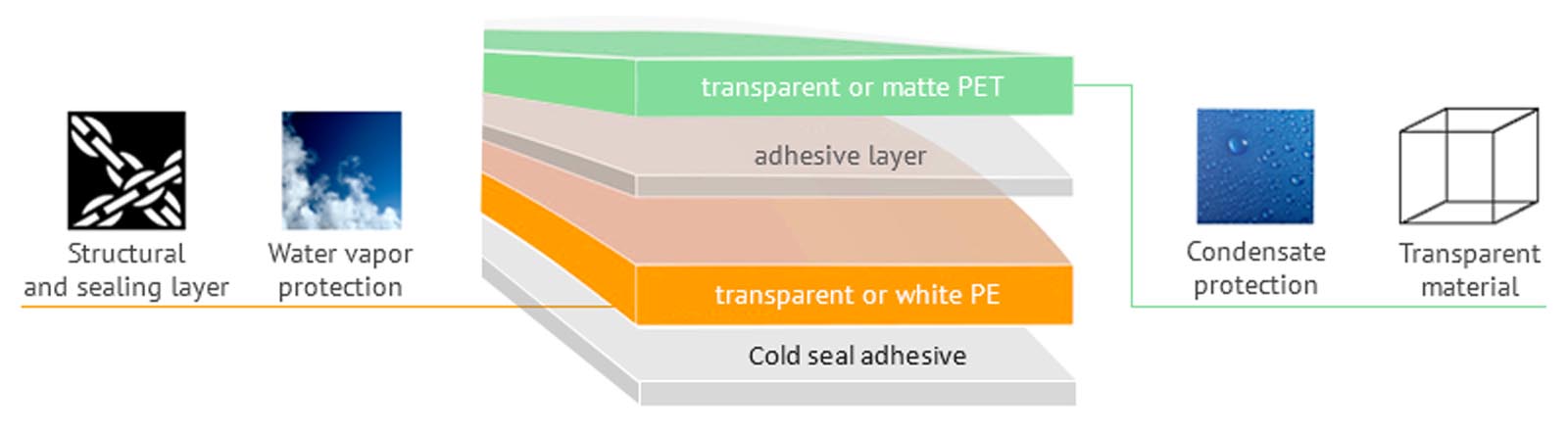

-

transparent or white PE (sealing and structural layer, good barrier against water vapours, high transparency)

SCHEME 2 : is a two-layer laminate. The choice between transparent or non-transparent composite depends on whether the customer wants a look-through part for product display.

Product Paramenters

|

Material Grade:

|

Food grade material

|

|

Material:

|

PET+VMPET+PE, BOPP+Kraft Paper+VMPET+PE, etc

|

|

Feature :

|

1).Safety Food Grade material & Perfect Printing

2).Great to prevent leakage, excellent Moiseture-Proof

3).Strong sealing Bottom & Durable Ziplock

|

|

Size&Thickness:

|

Custom based on your requirement

|

|

Ink type:

|

Eco-friendly Food Grade Soy Ink

|

|

Capacity:

|

100g, 200g, 250g, 500g, 1000g/1kg, 2kg, 5kg,8oz-100oz, Customized

|

|

Application:

|

Food / Coffee / Pet Food / Tea / Snack / Nuts / Whey Protein / Seed, etc.

|

|

Style Options:

|

Flat Bottom, Stand UP, Side Gusset, Zipper Top, With/Without Window, Euro Hole, etc.

|

|

Quality Control:

|

Advanced Equipment and Experienced QC Team will check material,semi-finished and finished products strictly in every step before shipping.

|

Food packaging roll film is commonly made from food-grade plastic materials, including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and sometimes even laminates with aluminum foil. These materials are chosen for their ability to provide protection, barrier properties, and compliance with food safety regulations.

Food packaging roll film is produced with strict adherence to food safety standards and regulations. This ensures that the packaging materials do not transfer harmful substances to the food and maintain the integrity of the product.

Food roll film can be sealed in various ways, depending on the packaging equipment and the specific requirements of the food product. Heat sealing, adhesive sealing, and zipper closures are commonly used to create secure and convenient packaging.